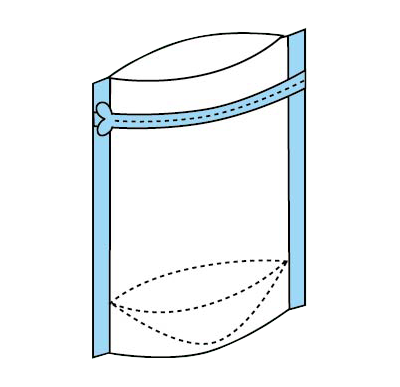

Side gusseted bag

back gusseted bag are the most common type of ordinary bags, with bad aesthetics; side gusseted bag move the heat seal to the side for better aesthetics. For upgraded bag types on the market like food bags, coffee bags, tea bags, chemical bags, etc., the front and back sides of those bag types can be designed with graphics and texts, and can be equipped with a vent valve, iron wire, deoxidizer, vacuum and nitrogen to enhance bag function.

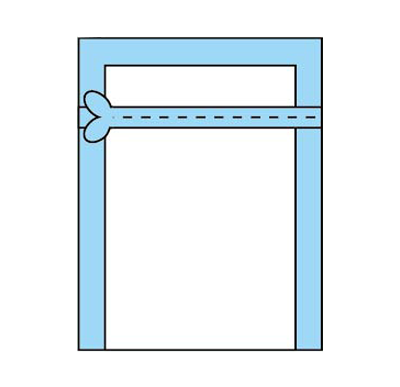

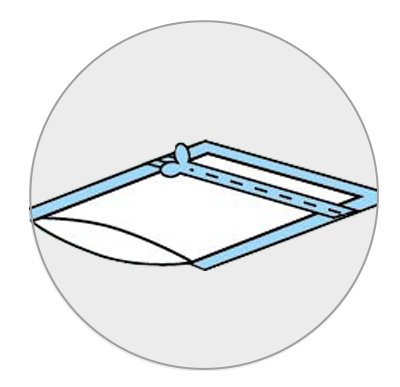

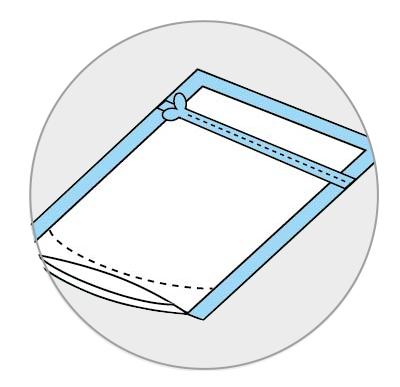

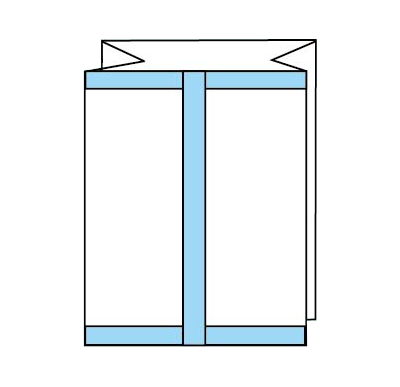

3-Side Seal

As the name suggests, a bag that is 3 sides sealed is suitable for different foods, tea bags, chemicals, vacuum series and other products. It is also commonly used in facial masks hand-carried kit packaging. Often used with different forms of hanging holes and tear notches to facilitate consumer storage and product display.

Stand up pouch(zipper)

The stand-up (zipper) pouch is a 3-side sealed bag with a base material, to make it into a stand-up pouch with zipper design. The packaging is simple in shape. Its bottom can be expanded to stand-up, presenting nicely. Currently, it is used in retail food packaging. All kinds of articles are packaged with zipper design, which can be repeatedly zipped-up and stored, so it has a basic moisture-proof function. Various hanging holes can be punched on the top of the bag body to facilitate hanging on the shelf, saving storage space.

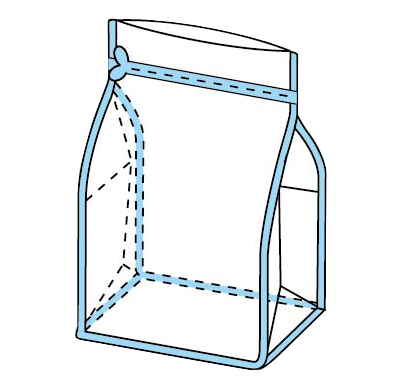

Flat-bottom bag/ Block Bottom Bag/ Box Bottom Bag with Pocket Zipper

The flat-bottom pocket zipper bag is a flat-bottom bag with a special zipper similar to clothes with pockets. Users can easily tear-open and reuse the seal. When standing, it is flat and stable with a nice appearance. The 4-side seamless and flat shape bottom of the bag is better for product display and shelf display. Moreover, richer artwork design and texture changes can be made on the front, back and sides, so that the 3D effect of the product can present the beauty of the design in multiple ways, making the product more attractive. Compared with traditional stand-up bags, a flat-bottom bag using the same amount of material can hold 35% more of content, which greatly reduces the cost of materials. It also provides the largest opening to ease the filling of food, and its zipper opening will not be contaminated by powders and become defected. In the recent 5 years, advanced countries in Europe and the United States have widely used it, and it is occasionally used for high-end products in Taiwan. Using it makes the product more valuable. It is a very good option.

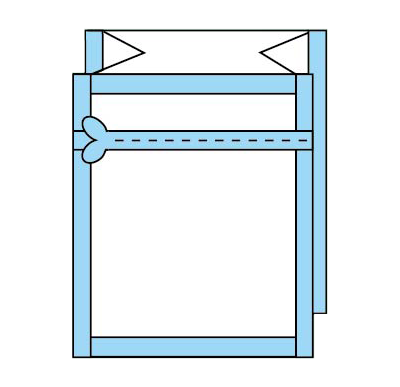

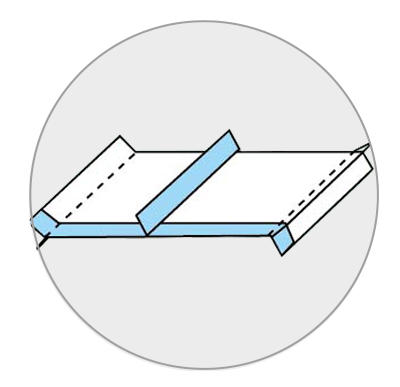

Flat-bottom bag with Standard Zipper/ Terminated Gusset Bag

For bag types like back-seal bags and quad seal bags, the bag seal has 4 layers and its opening is uneven. This bag type is to overcome this issue. 3cm~5cm below the opening that can be re-sealed is shrank from 4 into 2 layers as a perfect closing, to form a beautiful standing-bag shape, which is more good-looking than ordinary standing (zipper) bags.

Aluminum foil (bottle cap) series

There are 4 main types:

1. Aluminum foil + polypropylene: After filling the food into the container, heat seal the bottle cap, and then sterilize it with high-temperature water vapor, e.g. extended shelf life milk, soy milk, etc.

2. Aluminum foil + polyethylene + edible hot wax: After filling the food into a bottle or box, heat seal the bottle cap, e.g. Yakult

3. Aluminum foil + heat sealant: widely used in pharmaceutical packaging.

4. PET + aluminum foil + easy tear film: widely used in contact lenses and so on.

Box cover material and easy-to-tear sealing film series

All plastics firmly combine with other plastics with the same properties by heating. For example, Polyethylene (PE) bottles or boxes can only be covered with heated polyethylene (PE) film to produce an unbreakable seal. Similarly for Polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC) all have the same effect. Being sealed tight is good for some products, but most consumers prefer plastic films that do not need a knife to cut open. Therefore, the academic community has developed an easy-to-tear film. Through mixing a compound in the resin to create an easy-to-tear (EVA or EAA, etc.) special property.

Stylish bag

Bags are not only a square or rectangular shape, but can also be made into various shapes, such as cartoon shape or bottle/jar shape, to create visual arts and a more valuable out-look. The cost of production becomes relatively higher, because of the need to make a hot-seal hot knife and die. These can only be used once, and cannot be shared with other customers. Our company has 2 types of die-cutting machines, one of which is an exclusive rotary die-cutting machine, which is characterized by better opening performance than ordinary die-cutting machines.

Quad Seal Bag with zipper

A bag type with a ‘waist’ and ‘beautiful back’. Its difference from back seal bags and side-way seal bags is that there is no heat sealing line on the back or side. This bag type directly heat seals the 5 sides, which is a more aesthetic bag type. A pocket zipper can also be added to make the product more versatile.

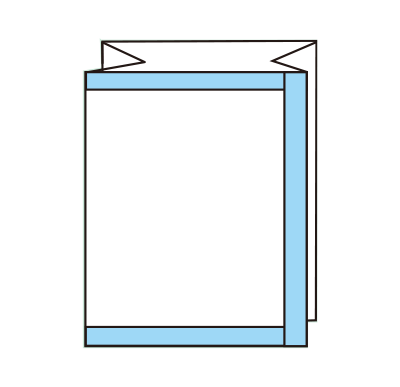

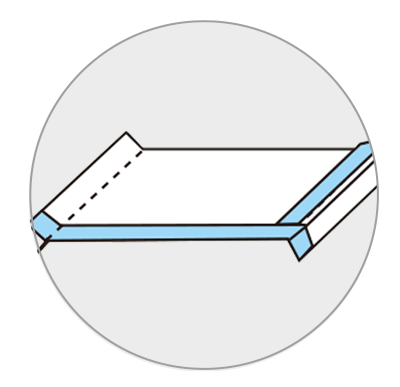

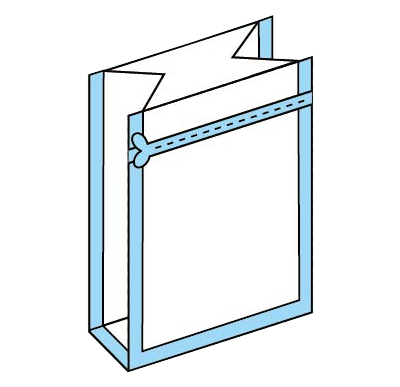

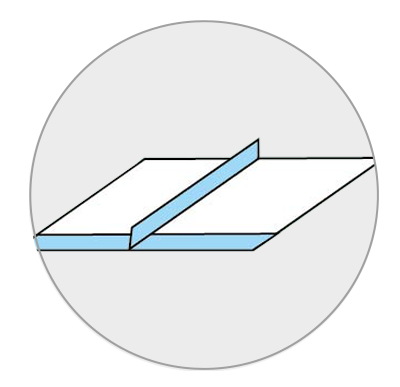

Back gusseted bag

A roll of film is rolled into a cylindrical shape, which is heat-sealed on the back, top and bottom. If you fold in 2 spots inward, the bag type that can be turned into a rectangular box, called a back-seal included-side bag, which can hold more items. This is the most popular bag type.

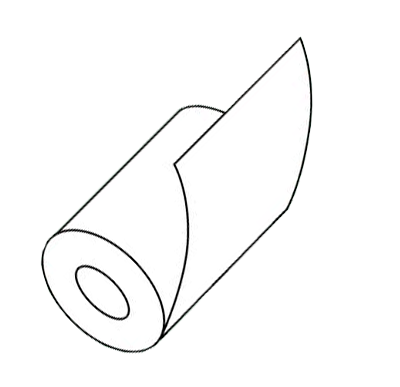

Rolls

According to the customer's needs, flexible packaging materials are cut into rolls, without making them into bags, which greatly reduces the cost. This is often used for fast packaging.

Heavy packaging bag

A bag that can withstand greater impact is called a heavy packaging bag. This bag type can be added with physical (prevents moisture, oxygen from penetrating, and better fall-proof, etc.) and chemical (acid and alkali resistance, durable compound, etc.) special properties. Our company has the industry's widest 1300mm full-process production line, and Taiwan's only Japan imported TOTANI 800 flat-bottom bag making machine, which can be aligned at both the top and bottom side, to make the largest flat-bottom bag.

Combo Bag

A combination bag that is transparent on one side and opaque on the other is called a yin-yang bag. In the market, the common structure is the combination of electroplated aluminum foil with transparent film or paper with transparent film. This is limited to being used in standing (zipper) bags. Our company developed a combination of real aluminum foil with transparent film or paper with transparent film, which can be used in flat bottom (pocket zipper) bags. All Packing is the only company in Taiwan to make special Yin-Yang bags.

Angle Plowed Bag with zipper

A complete sheet of flexible packaging material is folded and heat-sealed into a bag by machine. The biggest advantage is that it is less easily broken than a standing (zippered) bag, and various patterns can be printed on the bottom.