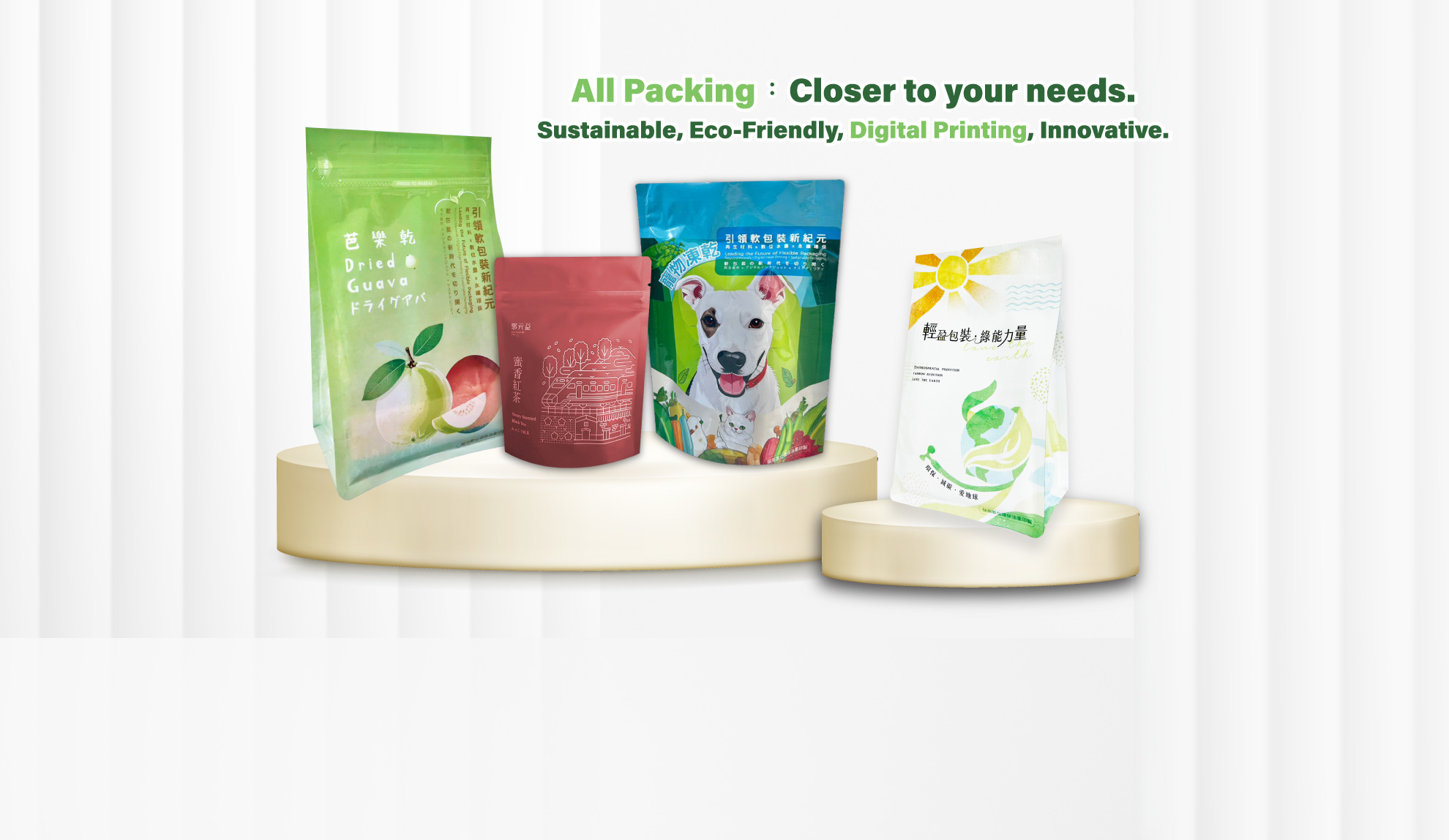

Company Profile

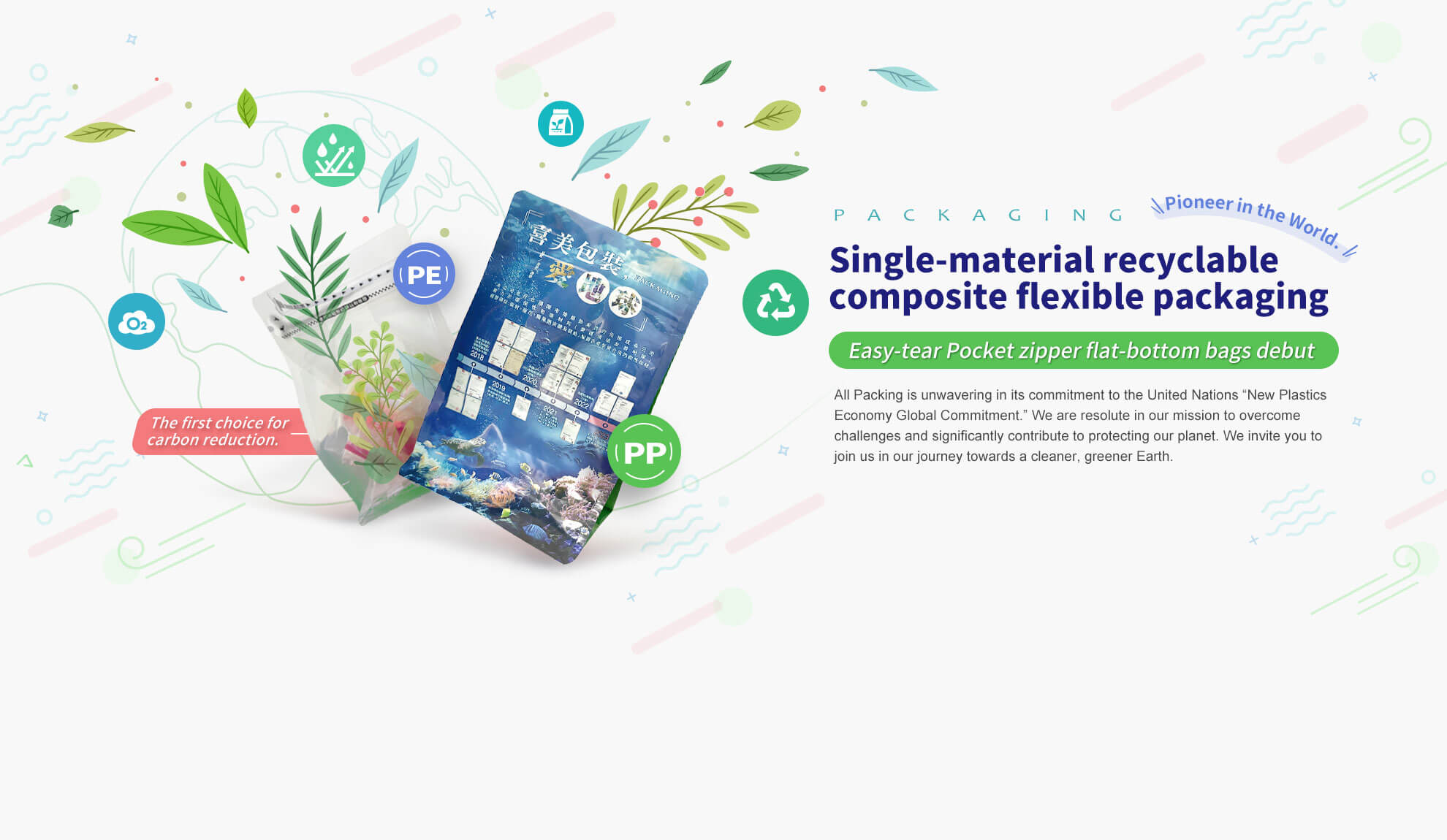

We mainly produce flexible laminated packaging materials in domestic and foreign markets. Focusing on design, production and manufacturing; upholding our management philosophy and spirit of "consistent", "genuine" and "innovative". We consistently pursue products and services that achieve the highest quality and highest customer satisfaction. All Packing’s customers are from the food, chemical, medical, electronics and other related industries. Good product packaging can not only enhance the added value of the product, but also attract consumers and gain customer satisfaction. Reduce wearout of the product inside the packaging, retain their full functions in terms of manufacturing process efficiency, shipping and storage. In addition, we make continuous improvements and innovations to better meet the international environmental protection trends. Let you be successful in every endeavor in the international market.

-

R&D

Produce various new packaging materials, and perform various experimental tests to see if they meet the physical, chemical and food preservation requirements of packaging materials.

-

Customer communication

Aiming at all kinds of packaging customers, listening to customers' demand, through communication and sharing, create packaging materials needed by customers and reasonable price services, to satisfy customers.

-

Design

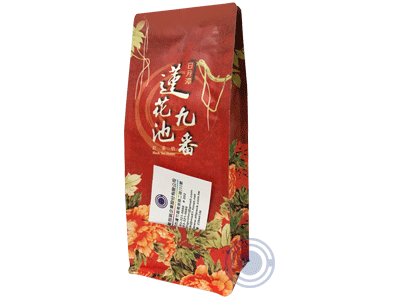

Objects are exquisite due to packaging. Our company provides professional layout design of various packaging material patterns, so that customers may get the packaging they want.

-

Cylinder/Drums

Mirror wheel finished with copper plating, grinding and polishing, using electronic engraving machines imported from Europe and the United States. The pattern is engraved with diamond needles on the copper plate to create perfect dots on the gravure. After finishing, use a chrome plating machine to strengthen the surface hardness, and then polish it into a mirror surface. After the final proofing is accepted, the best quality copper printing of the gravure printing machine is provided.

-

Printing

In the factory, benzene-free and ketone-free inks are used for color matching. The color development machine and color matching machine are used to accurately display printing colors, reducing printing staff’s man-hours on color matching and material consumption.

-

Product Inspection

After the film or paper is printed, a second inspection is performed by using the japanese NIRECO defect inspection machine and other equipment, to remove defective products such as pattern non-alignment, pollution, plate jams, etc. Check and remove through the precision camera to ensure printing quality before transferring to the next production step for further processing.

-

Gluing / Laminating

Mixing PE resin or other plastic resin to enhance functional properties. After heating, melting and extruding, the sheet film is casted through the T-DIE, and immediately combined with another 1 or 2 types of films through a composite pressing roller, which immediately cools and adheres to form a variety of packaging materials required for composite flexible packaging.

-

Sitting

Using a roll-to-roll method, adjust the knife to the proper position from the middle knife according to the pattern design or blank material, size, position. Cut out rolls or bags to be finished according to customer-specified quality requirements.

-

Bag Making

All kinds of bags in the workshop are made by different special machines. Simple bags can be made by 6M machines. Complex bags are made by large machines with a length of up to 38M. The main processing method is to heat-seal the composite plastic through the pressure, temperature, speed and time of the bag making machine.

-

Heavy packaging bag

Our company is the only one in Taiwan to import a TOTANI 800 flat-bottom bag making machine from Japan, which makes from all kinds of composite materials the largest flat-bottom bags, mainly used for containing food and pet feed. A high-quality patented carrier bag is about to be launched, completely overturning the engraved impression of today's carrier bag bags, achieving a truly seamless flat bottom, resistant to moisture and not easily to break.

-

Finished Product Inspection

To promise our customers the best quality and food safety protection, our company follows the principle of "no low-quality inflow, no low-quality output, no low-quality outflow" to guard every step. To perform inspection items such as film inspection, friction coefficient inspection, peel strength inspection, zipper opening- and closing-side strength inspection, and vacuum packaging test. In recent years, there have been numerous food safety incidents. The company is equipped with Japan's SHIMAD

-

Finished Product Shipment

Durable, stable and sturdy packaging is neatly stacked. Then each batch of goods is wrapped-well with a stretch film through an automatic film wrapping machine to ensure that there are no accidents such as fall-offs during the course of shipment to the client, thereby providing customers the most satisfying service.